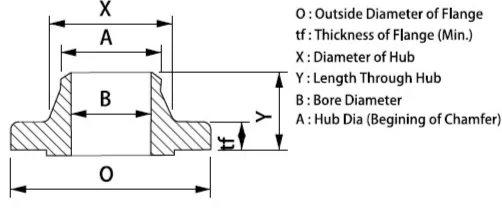

Weld neck flange welding are the most popular flange type with a neck extension with a weld bevel at the end. This type of flange is designed to butt weld directly to pipe to provide a superior and relatively natural form connection.

In larger sizes and higher pressure classes, this is almost exclusively the type of flange connection utilized. If only one bored flange style existed in modern applications, the weld neck would be your flange of choice.

Steel welding neck flanges (WN flanges) are a top choice for industries requiring durability and strength in high-pressure systems.Their unique design reduces stress concentration at the base, ensuring reliability in demanding environments. A reducing weld neck flange provides an ideal solution for connecting pipes of different sizes while maintaining system integrity.

With raised face and other face types available, these flanges offer versatility for various applications. The tapered hub design facilitates smooth stress distribution, making weld neck flanges a superior option for long-term performance.

The other noticeable feature of the weld neck flange is the tapered hub.

This type of connection provides a more gradual distribution of pressure forces along the transition from the pipe to the base of the flange, helping to withstand some of the shock from use in a higher pressure and higher temperature operating environment.

The mechanical stresses are limited given the extra steel material along the hub transition.

As higher pressure classes require this type of flange connection almost exclusively, weld neck flanges are often made with a ring type joint facing (otherwise known as RTJ face).

Also known as nozzle flanges or “long neck” flanges, these items were designed specifically with the pressure vessel and tank fabrication industry in mind.They are usually made as a one-piece construction with the intention of replacing a standard weld neck and pipe weld combination. The lack of a necessary weld connection is the defining feature of this flange style.

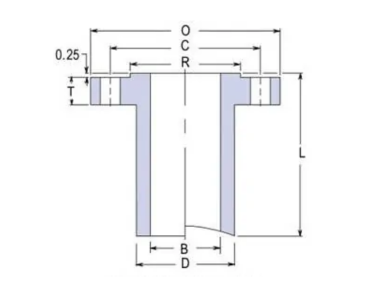

They usually have one straight thru bore with a square cut end (instead of the typical weld neck bevel). Generally, the bore size of the long weld neck is the exact same as the actual nominal pipe size but can be changed as necessary.The overall length of the nozzle flange is also up to the end user, and the body of the nozzle can be modified to some pre-existing sizes or custom sizes for additional reinforcement.

The base of the neck connecting to the base of the flange is slightly radiused to alleviate the abrupt perpendicular connection between both portions of the flange and to solidify the idea of a reinforced one piece construction.